Fabricate

In addition to projects cut at source, we can process slabs and blocks in our factory here in London. Whether from stock of our exclusive marbles, limestones and travertines or something that has been specifically procured at the architect or client’s bequest. We welcome technically challenging projects, finding solutions to ambitious concepts using experience and capability of our masons. Shaping, refinishing, jointing, polishing, thickening edges, perfecting mitres.

Controlled, Finished, Fast

GDS have specialised in procuring finished product direct from source, but our London factory adds yet another dimension to our service. Aside from the ability to supply bespoke projects, such as vanity tops, kitchen tops, reception desks etc. there are other benefits too. More technical elements of a particular project may be more suited to local manufacture To provide a better result. Or, when information is received last minute, cutting from slabs in stock may be the only option to hit dates.

Design Management

Cataloging slabs, digital rendering, technical drawings, intricate patterns, slip-matching, book-matching, dry lays, packing and delivery. The detailed work we do, design management from our London base ensures the result is perfect.

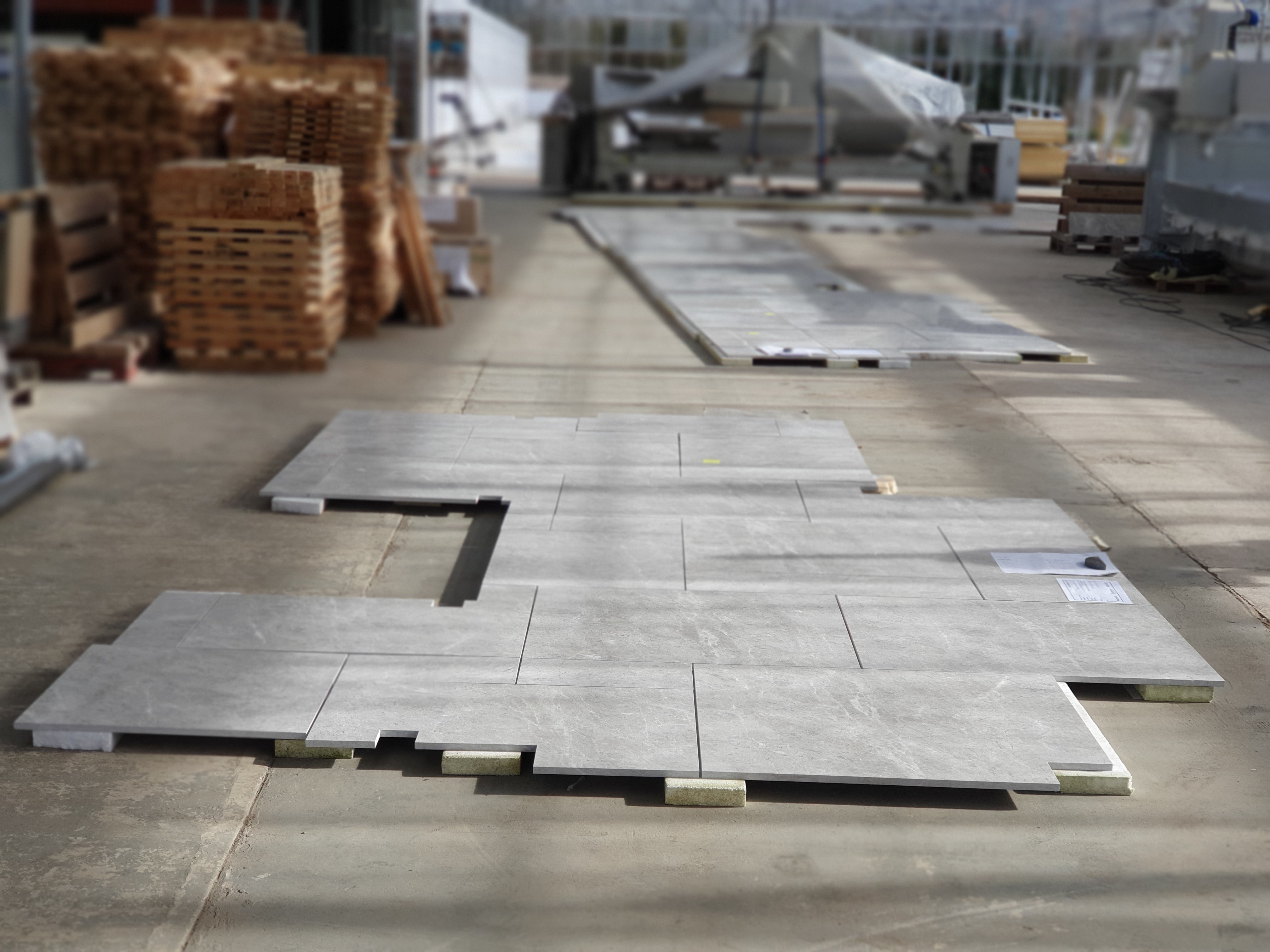

Dry Lays

Dry lays are an important part of quality control. We have 1000m2 to make extensive dry lays of every single tile, or just the space to open and spot check anything from source that needs some additional Q+A. With plenty of light and space to move it’s better to add the process with us and not on site.

Our Experience

Style matters, not scale. A project is only as big as you imagine it. We’ve beautified some of the world’s top hotels and heritage banks, 10,000 sqm retail spaces and single bathrooms. Making your vision a reality doesn’t have a size limit.